Check the pilot diameter

Mine is 3.124 with the vernier callipers

So 3-1/8"

Check the pilot diameter

Mine is 3.124 with the vernier callipers

So 3-1/8"

(1) 1995 Suburban 2500 4x4

(1) 1997 Astro

(1) 2005 Suburban (Papa Smurf)

THIS IS BOW TIE COUNTRY

Measurements need to be hole centers to centers, and diameters with clamps installed. If it uses U-bolts (smooth-bore holes, not threaded), they should have a parallel "flat" area that will be the approximate diameter. The edges of the yoke saddles may be beveled or relieved, so the true diameter may not be accurate on half of a bearing cup saddle measurement. Your saddle diameter isn't consistent with any listed joint I found. Are the cup saddle bolt holes threaded?

The shaft I have:

U-joint width 3" (loop centers, from polymer groove to groove)

Bearing cup dia. 1.125"

End to end (center of joint loops) about 32". The grease is hardened, so I can't tell how compressed it is. It moves, but very little, and I didn't want to force it.

Screw-on compression slip-yoke seal (press-on seal seems to be different for some joint brands)

20210916_131257_01.jpg

The flange I have is of the polymer retained type (Uses the inner C" type snap rings for service.

My flange measures 1.125" bearing diameter.

Some of these shafts used the CV (Double Cardan) joints and some did not.

My flange is the single cardan type...

Seems that Gregs Shaft and my flange might make it giddyupgo.......

(1) 1995 Suburban 2500 4x4

(1) 1997 Astro

(1) 2005 Suburban (Papa Smurf)

THIS IS BOW TIE COUNTRY

Yes, the bolt holes in the u-joint axle yoke are threaded - in the bottom half of each hole. The area I measured for bearing cup diameter on the yoke is a parallel portion of the U shape. But, I was on my back beneath the vehicle with my dial caliper in an awkward position, so the measurement could be a little off.

Your driveshaft seems to be ~ the right measurement, and should be about the length it needs to be with the addition of the flange Robyn has.

If you agree, let me know how to proceed... Thanks, Jim

Contact Me

Lil Red - Duramax 6600 Conversion

Content Web Site

The Diesel Page - 6.2L/6.5L Diesel Books

The 6.2L/6.5L Troubleshooting & Repair Guide

Duramax Diesel Conversion Guide

Duramax Diesel Service Guide - How to Replace Head Gaskets, Injectors, Water pump, and more - New!

Photo Album

TDP Youtube Channel - New!

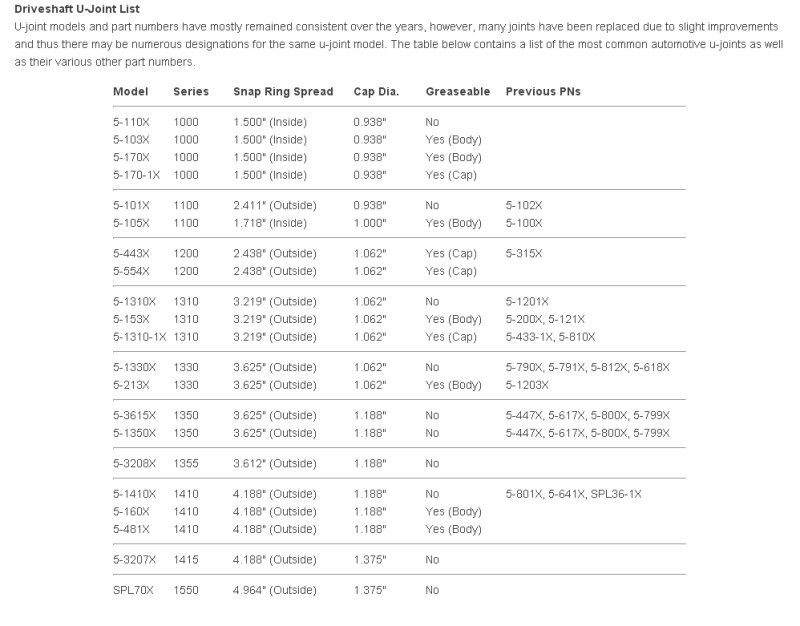

The joints you are dealing with are not shown in the chart.

1.125" Diameter bearing cups....(GM/Saginaw 3R Joints) Spicer number 5-3147

Just happen to have a couple of these Bad Boys on the shelf for the Snow Cat shaft.

The 3R Saginaw has 1.125" cups...Just slightly smaller than the 1350 Spicer.....the overall width is slightly larger than the 1350 at 3.650"

Basically the 3R is about the same strength as a Spicer 1350

Last edited by Robyn; 09-18-2021 at 06:51.

(1) 1995 Suburban 2500 4x4

(1) 1997 Astro

(1) 2005 Suburban (Papa Smurf)

THIS IS BOW TIE COUNTRY

Thanks Robyn,

Pls send me the flange, and I'll check it out for fit. Sounds like it'll work with the front driveshaft Greg has.

Jim

Last edited by More Power; 11-16-2021 at 09:38.

Contact Me

Lil Red - Duramax 6600 Conversion

Content Web Site

The Diesel Page - 6.2L/6.5L Diesel Books

The 6.2L/6.5L Troubleshooting & Repair Guide

Duramax Diesel Conversion Guide

Duramax Diesel Service Guide - How to Replace Head Gaskets, Injectors, Water pump, and more - New!

Photo Album

TDP Youtube Channel - New!

A local friend and TDP member passed away last month. I'll be attending his memorial service this Saturday. I learned from a mutual friend that he had a mostly complete 6.5TD engine, and that his widow was wanting to reduce the clutter. I stopped by this afternoon to express my condolences, and to help with the clutter... I bought the engine... Came with most of a shopping cart.

It remains to be seen what condition the moving parts are in, but I do know that the intake had been off of it for quite a while, and that the intake runners in the cylinder heads have some surface rust inside. The engine had been stored inside a building, but little else was done to keep the crud out of it. The crank didn't want to rotate with light effort... A bit greasy and looks well used, but it's a "599" block and had been an HD electronic engine (HD intake manifold). No holes in the pan, and the crank pulley and damper look to be in the right place... Jim

Last edited by More Power; 06-26-2024 at 10:36. Reason: stuff

Contact Me

Lil Red - Duramax 6600 Conversion

Content Web Site

The Diesel Page - 6.2L/6.5L Diesel Books

The 6.2L/6.5L Troubleshooting & Repair Guide

Duramax Diesel Conversion Guide

Duramax Diesel Service Guide - How to Replace Head Gaskets, Injectors, Water pump, and more - New!

Photo Album

TDP Youtube Channel - New!

Extra parts are always nice to have.

90 Chev 3500 c/c 4x4,6.2na,400 auto,4:10 gears.DSG Timing gears,main girdle, isspro tach, pyro,boost,oil and trany temp.Dual Tstats, High volume peninsular pump,on shelf, Custom turbo and intercooler 85%complete. Change of plans for the dually, it's going to get a Cummins. Both trucks are Blue 90 4x4 crews

Could be a great score......

Yank the glow plugs and squirt the holes well with some sea foam or other good skunk pizz....

Let it set for a week or so.....

(1) 1995 Suburban 2500 4x4

(1) 1997 Astro

(1) 2005 Suburban (Papa Smurf)

THIS IS BOW TIE COUNTRY

We think a lot alike! I had done most of that. The glow plugs on the turbo side of the engine are harder to get to. I did the other side, as well as squirt some WD and motor oil into the intake runners in the heads. I'm hoping I'm pleasantly surprised when I get it apart.

Contact Me

Lil Red - Duramax 6600 Conversion

Content Web Site

The Diesel Page - 6.2L/6.5L Diesel Books

The 6.2L/6.5L Troubleshooting & Repair Guide

Duramax Diesel Conversion Guide

Duramax Diesel Service Guide - How to Replace Head Gaskets, Injectors, Water pump, and more - New!

Photo Album

TDP Youtube Channel - New!

With the engine out the glow plugs should be easy to get to....

Pop the bolts out on the little tubes that protect the wires and get right in there....

(1) 1995 Suburban 2500 4x4

(1) 1997 Astro

(1) 2005 Suburban (Papa Smurf)

THIS IS BOW TIE COUNTRY

Thanks to Robyn and Greg for the front driveshaft parts! I'll post a pic once it's ready to go in.

Here's what the engine looks like as of about 15 minutes ago. Painted and the reassembly started. Hoping to get it set into the chassis this coming weekend. I had already installed all of the fittings so I could pre-oil the engine. My trusty battery powered drill/driver could muster 35 lbs of oil pressure. Interesting how much power the oil pump takes once pressure has been developed on a cold engine.

It's pretty nice inside. We had power connected this weekend so we could run the windows up/down to replace the lower window seals for the side windows - rubber strips that seal against the glass. The new parts improve the look a lot, as will a new windshield.Of course, we discovered that the driver's side power window regulator was crap... so a new one was installed. Sounds easy... We replaced the rubber lip seals on the inside/outside of the window channel while the door panel was off. That sounds easy too... Needed to re-staple the new lip seal to the door panel. Door panels are a bit fragile. We were careful, and did a good job. The new power window regulator works perfectly. Sarah learned what happens when you push the power window button on the door... or what happens when it doesn't move the window.

What do all those things do? The parts I'm holding appear to be the oil cooler lines... Just kidding...So much wiring! All those wires look like a lot of fun... I knew that "now" was the time to make any needed wiring harness repairs and clean the harnesses up a bit. I changed out the complete glow system harness, and replaced it using a new harness that had ceramic electrical connectors. I had accumulated quite a few new/like new/improved 6.5 parts through the years. I used as many as I could on this build, which stepped up the appearance/functionality of the engine installation.

Jim

We need your help too! Did this forum thread or YouTube video help you with your 6.5L Turbo Diesel? Would you like to share this information with others or help us get the word out about the 6.5? It's easy! Simply link to us in your own YouTube video, or post the link(s) shown here in a forum post, email message or social media site. Thank you!

thedieselpageforums.com/tdpforum/showthread.php?46770

https://youtu.be/9Il2deqwXLA

Last edited by More Power; 12-10-2024 at 13:58.

Contact Me

Lil Red - Duramax 6600 Conversion

Content Web Site

The Diesel Page - 6.2L/6.5L Diesel Books

The 6.2L/6.5L Troubleshooting & Repair Guide

Duramax Diesel Conversion Guide

Duramax Diesel Service Guide - How to Replace Head Gaskets, Injectors, Water pump, and more - New!

Photo Album

TDP Youtube Channel - New!

Looking great.

I love the interiors of the earlier GMT400

(1) 1995 Suburban 2500 4x4

(1) 1997 Astro

(1) 2005 Suburban (Papa Smurf)

THIS IS BOW TIE COUNTRY

After working on the engine harnesses and a few other misc items on Sunday, to prepare for the engine install, we got the engine set into the chassis yesterday.

So far, after getting the engine in, we've reconnected the motor mounts, trans bell-housing, oil cooler lines and a few other misc items. Most of the engine brackets and accessories had already been bolted to the engine prior to the installation (starter, ex manifolds, DS4, water crossover/t-stat, vac pump, ps pump, injectors, glow plugs and fuel return hoses/lines). Didn't install the steel fuel injector lines or intake manifold because I wanted to use the space in the engine valley to make it easier to install the top two trans bell-housing bolts and the fuel line/harness brackets that attach to those bolts. Here's how it looked just prior to going in...

Looks good seeing it in there. More work than I remember though... due to not having a vehicle lift and the fact that the transmission was already in the Blazer. We needed to tilt and rotate the engine (as it was suspended by our engine hoist) as it went in, and my daughter suggested I use motorcycle ratchet straps to do the tilting and rotating... Great idea!

Last edited by More Power; 09-20-2024 at 20:36.

Contact Me

Lil Red - Duramax 6600 Conversion

Content Web Site

The Diesel Page - 6.2L/6.5L Diesel Books

The 6.2L/6.5L Troubleshooting & Repair Guide

Duramax Diesel Conversion Guide

Duramax Diesel Service Guide - How to Replace Head Gaskets, Injectors, Water pump, and more - New!

Photo Album

TDP Youtube Channel - New!

Looking good. I bet you cant wait to drive it again.

"The Constitution is not an instrument for the government to restrain the people, it is an instrument for the people to restrain the government."

-Patrick Henry

A5150nut

2006 K3500 D/A

94 6.5 4x4 5spd Sold

One tool for the tool box IF YOU DON'T HAVE ONE

15mm Gear wrench ratcheting box open end with flex head

The two top bolts can be put in quite handily with one of those wrenches.....

I tossed the stud top bolts that were in that location as far as I could throw them.....

The fuel line bracket bolts there and the locking nuts that were on the top of the stud ends started turning the bolt....Made a nasty job of that area....

I made a little bracket to bolt elsewhere to hold the fuel lines....

I also tossed the stock fuel manager in the dirt and mounted a Racor up front on a bracket that shared holes with the ABS unit....

Far easier to get to.

With the fuel filter out of the way....the two top bolts are a breeze....

About the only other thing in that area is the big main engine harness plug....

A set of those Gear Wrench's with flex heads are the cats Azz.....in SAE AND METRIC....

Going where other tools can't.....

Get a little movement...or a lot.

Another secret.

Remove the frame portion of the RH front motor mount.

Lower the engine in and it will slide right in and then over against the LH mount. Hold with the hoist...

The put the frame portion back in and you are golden

The Bell housings tend to hit the tunnel (Older the rig the more the body has settles )

Having the front tire on the RH side off and the rubber inner fender flap off.....You can get to the glow plugs easily....accept #8

Also the starter front support and the wires are all right there within easy reach......

On the Dahooooley I cut a mouse hole ...Actually a rat hole in the inner fender back by the area where the heater hose connects.

Gets ya to the heater hose and #8 glow plug.

Added a little cover plate held in with a sheet metal screw.

I do believe pics were posted back in the day....2014 IIRC .....

I hate fighting stuff.....Also reduces the BLUE AIR and the need for BANDAIDS...

Middle picture in the referenced post...this is the view through the Rat hole.....Easy to change the heater hoses and glow plug#8

If you decide to make the RAT hole....Be very careful in the area as the main wiring harness from the ECM is right in there.....Sheet metal shoved in to protect things is a must have.

Second pic from the left shows the red bolt....Starter support....This area is where all the starter wires are too...

Glow plugs are a snap..... Also the number 8 injector is right there AND THE RUBBER PLUG on the rear nipple too.

I can get my hand and tools in THE RAT HOLE

https://www.thedieselpageforums.com/tdpforum/showthread.php?t=43423&highlight=CHANGING+GLOW+PLU GS

Last edited by Robyn; 10-05-2021 at 15:56.

(1) 1995 Suburban 2500 4x4

(1) 1997 Astro

(1) 2005 Suburban (Papa Smurf)

THIS IS BOW TIE COUNTRY

I hate fighting stuff.....Also reduces the BLUE AIR and the need for BANDAIDS...

The passenger side head is right up against the fiberglass pad. Amazingly tight. The packaging musta been designed without padding. My hands were all itchy and beat up (but not too bloody) when I finally called it a day. What remains of the underneath stuff is easier to get to, so it'll not be too bad.

I remember back when I installed the 6.5 in our Power Project truck, that I removed the frame half of the motor mounts (part with the rubber) and just bolted new ones to the engine half of the mounts - on the engine, then set the engine in that way. Getting the engine sitting in the chassis was real easy, but getting the frame half of the mounts bolted to the frame took a couple hours... It's really tight, and you're working with lock nuts that don't turn easily, and you can't get more than about an 1/8th of the turn at a time. A little blue air, maybe...

Contact Me

Lil Red - Duramax 6600 Conversion

Content Web Site

The Diesel Page - 6.2L/6.5L Diesel Books

The 6.2L/6.5L Troubleshooting & Repair Guide

Duramax Diesel Conversion Guide

Duramax Diesel Service Guide - How to Replace Head Gaskets, Injectors, Water pump, and more - New!

Photo Album

TDP Youtube Channel - New!

On the Dahoooley the frame mounts went in easy...

Used a wiggler and a helper...Took 5 minutes maybe.....

The lock nuts are not a big help though....

(1) 1995 Suburban 2500 4x4

(1) 1997 Astro

(1) 2005 Suburban (Papa Smurf)

THIS IS BOW TIE COUNTRY

Daughter is pretty excited to be able to drive it. This is the first vehicle she's expressed this level of interest "in the vehicle", aside from just basic transportation. I'm happy for her. I felt/feel that way about a lot of vehicles I've owned through the years, especially those I put significant sweat equity into. She's seen the very inner parts of the engine. She helped install the cam bearings, cam, crankshaft, rods and pistons and everything that followed. She'll have a level of understanding about what makes a motor run that she didn't have before... assuming it all works.

Contact Me

Lil Red - Duramax 6600 Conversion

Content Web Site

The Diesel Page - 6.2L/6.5L Diesel Books

The 6.2L/6.5L Troubleshooting & Repair Guide

Duramax Diesel Conversion Guide

Duramax Diesel Service Guide - How to Replace Head Gaskets, Injectors, Water pump, and more - New!

Photo Album

TDP Youtube Channel - New!

This is a great thing for the young lady......Not that many girls get to this level of understanding of "The ways of the force"

Far too many never get beyond the turn the key and go....

Getting ones hands dirty brings the entire picture into focus....really well.

(1) 1995 Suburban 2500 4x4

(1) 1997 Astro

(1) 2005 Suburban (Papa Smurf)

THIS IS BOW TIE COUNTRY